Despite elaborate surface treatment of all individual parts and careful lubrication with resin-free, synthetic oils and greases, every mechanical watch is subject to wear. A regular service by our watchmakers ensures that your Lange watch functions as perfectly as on the first day over the long term.

Complete service

Our service covers three areas: overhaul of the movement, refurbishment of the case and replacement of the leather strap or refurbishment of the precious-metal bracelet. The costs for service depend on the degree of complication of the watch and other necessary work steps. You can view sample prices for service performed in our manufacture here.

Restoration

If malfunctions occur due to external influences such as impact or penetration of water, these are rectified as part of a repair. Severe damage can also be dealt with through repair or replacing parts. An individual cost estimate is created for this.

Repair of historic A. Lange & Söhne watches

We offer a service of repairing historic Lange watches in our manufacture. Should you own a Lange watch and wish to have it repaired, please contact the service department by sending an e-mail to team_service@lange-soehne.com.

Please understand that we cannot repair pocket watches from other manufactures.

Certificate for historic A. Lange & Söhne watches

If you require detailed information about your historic Lange watch, please contact the German Watch Museum Glashütte. The foundation is in possesion of all historic company documents of A. Lange & Söhne. You will receive an official certificate of origin as well as copies of all sales documents:

Service request

Please note that due to the current situation, longer processing times for revisions and repairs in our service centers are to be expected.

CASE REFURBISHMENT

1. Disassembly and cleaning

The movement is stripped first of all. This means that the case and movement are separated from each other and the hands and dial are removed. All damage is thoroughly documented. The parts of the case are then thoroughly degreased and cleaned with special liquids.

2. Lug correction

Hard impact on the case, such as when the watch falls to the floor, may lead to the lugs becoming bent. When the case is refurbished, the lugs are returned to perfect alignment in order to reliably hold the strap and the entire watch once again. Even lugs which have broken off can be restored.

3. Repairing scratches and notches (laser welding)

One of the most important techniques in visually treating a watch case is laser welding. Deep scratches or notches can be filled with the original material instead of the case being polished to the deepest point of the notch. To do this, a 0.1 mm wire made from precious metal is melted onto the damaged area using a laser beam.

Excess material at the laser points is ground flat and smoothed. All damaged areas are processed so that nothing can be seen after polishing. Thus the case is preserved in its original condition and can be repaired in this way many more times.

4. Polishing

To seal the surfaces, they are treated with a rotating brush and a fine polishing paste. To return the parts of the case to their original appearance, there is another round of polishing with a wool wheel and polishing paste. Gradually, the required sheen is achieved.

The refurbishment of the case also includes the lugs and push pieces as well as the crown and buckle. All surfaces are polished carefully by hand in several work steps. For polishing, we use the finest paper and brushes made from goats’ hair or wool.

5. Cleaning and assembly

Once all damage has been dealt with, the individual parts of the case are cleaned and dried before the watch is put back together. All seals are also renewed. The final inspection then takes place.

MOVEMENT OVERHAUL

1. Disassembly and cleaning

Once the watch is uncased, the movement and case are separated and the dial and hand are removed, the movement is disassembled into its individual parts. The parts are then thoroughly degreased and cleaned with special liquids.

2. Inspection and refurbishment

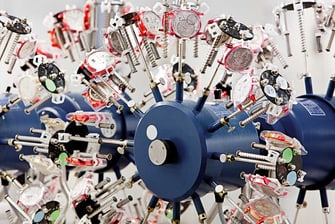

The individual movement parts are now carefully scrutinised. Depending on the model, the watchmakers may have to examine several hundreds of parts, which are replaced if they exhibit even the slightest damage or sign of wear.

3. Assembly and lubrication

The movement is then reassembled with great care. The bearings and functional surfaces are lubricated with the oil dispenser, a tiny metal needle along which a droplet of oil can glide. Different oils and greases are used to do this. They are applied to the respective defined oil point in precise quantities. This allows your watch to continue running smoothly for many years to come.

4. Adjusting

Once the rate accuracy of the watch has been checked with a timing apparatus, it is adjusted in five different positions. With minimal shifts of weight, the balance is poised and the duration of its oscillations is gradually optimised to guarantee maximum rate accuracy.

5. New seals

All seals are renewed to prevent the penetration of water and dirt. This affects both the glass seals on the bezel and base glass as well as case seals on the middle section, the crown and all push pieces.

6. Test and final inspection

All mechanisms on the fully assembled movement are checked to ensure they are functioning perfectly. This is followed by a several-day bedding-in phase on a watch winder and a power-reserve inspection.

The reassembly of the movement and case is followed by a second several-day test phase. In the stringent final inspection of the watch, alongside the visual refurbishment, it is examined for water resistance, functions and rate accuracy one last time.

Explore further